Opening or closing valves in the wrong order can have disastrous consequences and cause fatal injury to operators. It can also lead to product spills, plant and equipment damage and environmental pollution. A valve interlock system is a simple mechanical device, which can be customised to implement a safe sequence of operation in any process activity. Valve interlocks provide effective protection of investments in plant and equipment. They also improve employee safety and reduce the risk of damage to the environment.

For hand wheel- and lever-operated valves

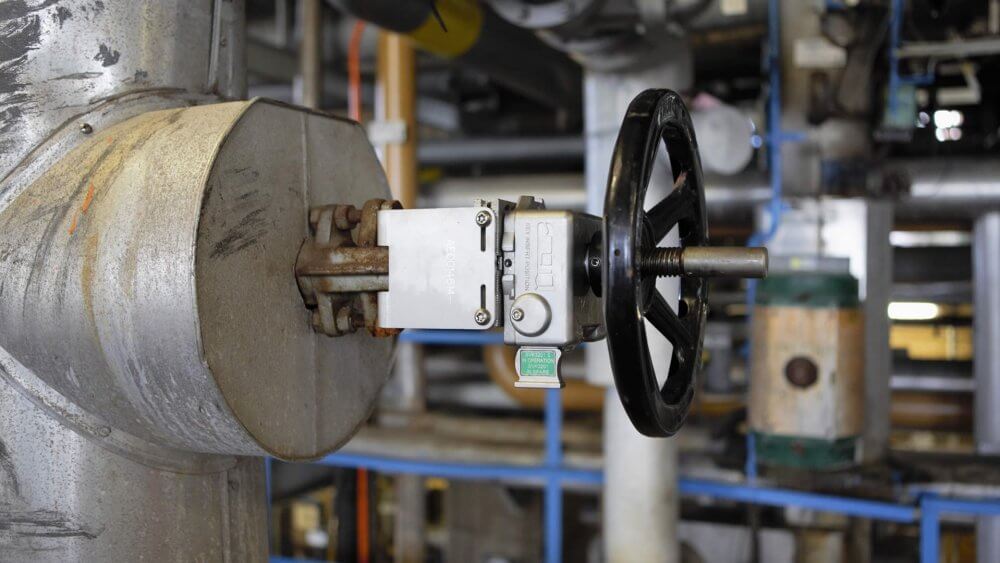

Sofis valve interlocks suit all types of lever- and hand wheel-operated valves, including ball, butterfly and plug valves and gate, globe, and gear-operated valves. Available in single-key or double-key versions, they lock the valve in either an open or closed position. The valve can also be locked in an open or closed position as part of an operating sequence. Depending on its position in the sequence, it can sometimes only be opened and at other times only be closed.

No alteration to the host valve

Valve interlocks can be mounted without any alteration to the host valve. The characteristics of the valve remain unchanged. The valve interlock system is installed as an integral part of the valve, with the original valve lever removed and replaced by the interlock with a new sliding lever or hand wheel.

Applications of the valve interlock system

Valve interlocks are used in situations where safe and right-first-time valve operation is required. They safeguard people and force them to follow procedures, as well as protecting equipment and the environment. Valve interlocks are used for a wide variety of applications, such as pressure relief valves (PRVs), pig launching and receiving, decoking, inert gas systems, pump start-up, flare lines, boiler blowdown, 2 out of 3, chemical dosing pots, HP fuel gas heaters, closed drain drums, vessel filling, vessel isolation, gas train alignment and pump routing.